Highlights:

- Importance of regular maintenance for vending machine success with our vending machine maintenance checklist

- Conducting visual inspections to identify issues early

- Effective inventory management and restocking strategies

- Steps for routine cleaning and sanitization

- Updating payment systems to meet customer preferences

- Scheduling mechanical and technical inspections

- Maintaining detailed maintenance records for optimal performance and regulatory compliance

Intro to the Vending Machine Maintenance Checklist

Operating a vending machine business can be a lucrative endeavor, especially in high-traffic areas where people are constantly on the go. However, the success of your vending operation relies heavily on regular maintenance to ensure that machines are functional, stocked, and appealing to customers.

This is where a comprehensive vending maintenance checklist comes into play. By following this guide, business owners can keep their machines in top condition, minimizing downtime and maximizing profitability.

Conducting Regular Visual Inspections to Spot Issues Early

Regular visual inspections are essential to identify potential issues before they escalate. Begin by examining the exterior for visible damage, such as dents, scratches, or rust. Verify that the buttons function properly and that the display screens are clear and legible.

Proceed to inspect the interior components, including the coin mechanisms, bill validators, and product dispensers. Look for signs of wear and tear, such as frayed wires or loose connections. By keeping an eye on these elements, you can catch problems early and avoid costly repairs or replacements.

Ensuring Proper Inventory Management and Restocking

Efficient inventory management is vital for maintaining a successful vending operation. Regularly check inventory levels, at least weekly or more frequently for high-traffic areas, to ensure your machines are well-stocked. Track product sales to identify popular items and slow movers, allowing you to restock accordingly and make informed decisions about product selections.

Rotate stock to prevent items from becoming stale or expiring, particularly for perishable goods. Keeping a well-organized log of sales and inventory will streamline the restocking process, helping you maintain optimal product availability. A methodical approach to inventory management not only boosts customer satisfaction but also enhances sales and operational efficiency.

Performing Routine Cleaning and Sanitization

Regular cleaning is essential for both maintaining your machines’ appearance and ensuring customer health and safety. Start by cleaning the exterior to remove dirt, fingerprints, and any sticky residues. This helps keep your machines looking appealing and inviting to potential customers.

Next, turn your attention to the interior. Remove any expired products and wipe down surfaces with a sanitizing solution. Make sure to clean high-touch areas like buttons and handles thoroughly, as these spots can harbor germs. Regular sanitization of these areas can help prevent the spread of illnesses.

For refrigerated vending machines, it’s crucial to clean and sanitize the cooling units and compartments to prevent mold and bacteria buildup. This not only preserves the quality of your products but also ensures that they remain safe for consumption.

Lastly, clean the dispensing mechanisms to ensure they are free of debris, which can affect their operation. Regular cleaning of these parts helps maintain smooth functionality and prevents jams or malfunctions. By incorporating these steps into your vending maintenance checklist, you ensure that your machines remain in top-notch condition, appealing, and safe for customers.

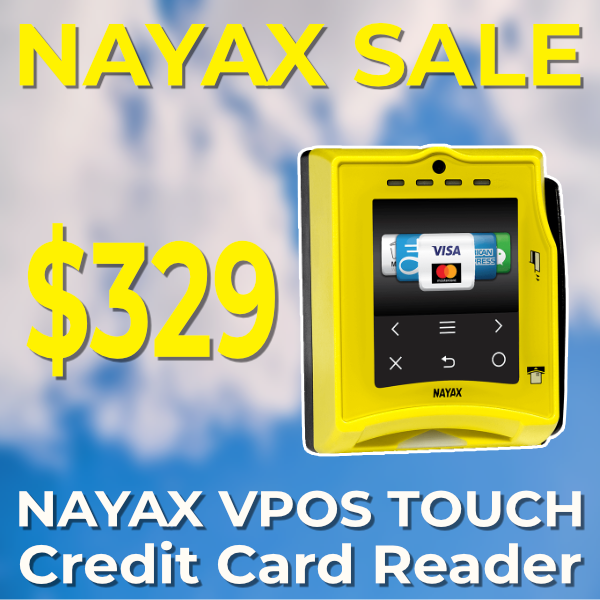

Monitoring and Updating Payment Systems Regularly

In today’s cashless society, updating your payment systems is crucial to staying competitive. Ensure your vending machines accept a variety of payment options, including credit cards, mobile payments, and contactless transactions. Regularly test these systems to confirm they are functioning correctly, as any malfunction can lead to lost sales and customer dissatisfaction.

Stay informed about technological advancements in vending payment solutions, as customer preferences and payment methods evolve rapidly. For instance, integrating newer technologies like QR code payments or app-based systems can enhance convenience for users.

Additionally, periodically review transaction data to identify any issues or patterns that could indicate potential problems. By offering multiple, reliable payment options, you cater to a broader customer base and improve overall user experience, driving increased sales.

Scheduling Regular Mechanical and Technical Inspections

Ensuring that your vending machines operate smoothly and efficiently goes beyond simple visual checks; regular mechanical and technical inspections are critical. Employing a qualified technician to perform thorough evaluations of internal components such as motors, sensors, and cooling systems is key. These professionals can detect subtle signs of wear and tear that might escape a casual glance, addressing small issues before they become significant problems.

Routine mechanical inspections should also include testing and calibrating sensors to guarantee accurate product dispensing. Additionally, checking the condition of wiring, connectors, and electrical components helps prevent potential failures that could disrupt service.

For machines that dispense refrigerated items, inspecting the cooling systems ensures that they maintain proper temperatures, safeguarding product quality and customer safety. This is particularly crucial during warmer months when cooling units work harder and are more susceptible to strain.

Technicians should also verify that all moving parts are lubricated and functioning as intended. Regular adjustments and fine-tuning can optimize machine performance, reducing the likelihood of breakdowns.

By prioritizing these in-depth inspections, you not only enhance the reliability and longevity of your vending machines but also improve customer satisfaction by minimizing downtime and ensuring a consistent, high-quality vending experience.

Keeping Detailed Maintenance Records for Optimal Performance

Maintaining detailed records of all maintenance activities is essential for the long-term success of your vending operation. Accurate documentation allows you to monitor the condition and performance of each machine over time, making it easier to identify recurring issues and anticipate when components may need replacement.

A well-organized maintenance log should include specific details such as the date and type of inspection, the actions taken, and any issues or observations noted. This can encompass everything from routine cleanings and restocking to mechanical and technical checks. By recording this information, you gain valuable insights that can inform your future maintenance schedules and strategies.

In addition, detailed records can help you spot patterns that might indicate underlying problems, such as frequent malfunctions in a particular part of a machine. Addressing these issues proactively can save you time and money in the long run by preventing larger, more costly repairs.

These records are also beneficial for regulatory compliance and quality assurance purposes. In the event of an audit or inspection, having a thorough maintenance history readily available can demonstrate your commitment to maintaining high standards of operation.

Furthermore, well-maintained logs can be invaluable if you need to make warranty or insurance claims, providing proof that you have diligently cared for your equipment. Overall, keeping detailed maintenance records not only ensures optimal performance but also enhances the reliability and profitability of your vending business.